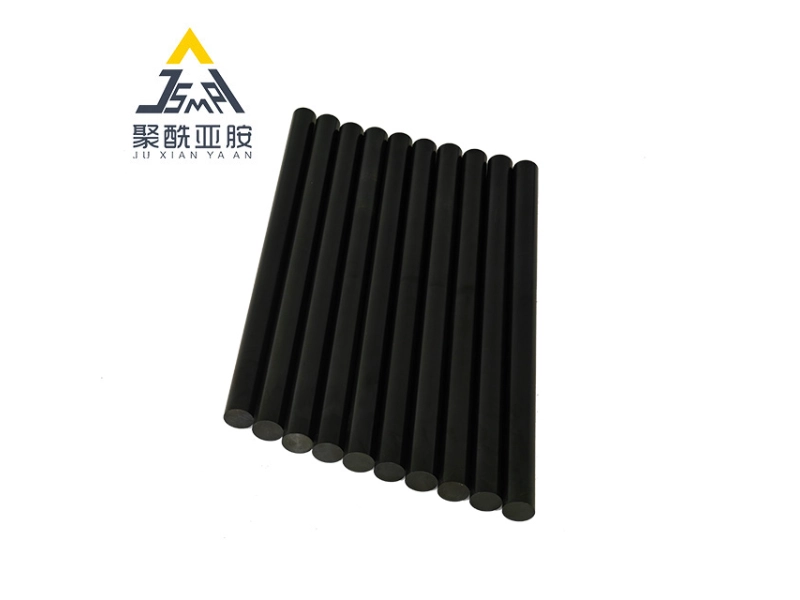

Conducting Polyimide Strips: Discovering New Options in Design

In the realm of innovative materials, conductive polyimide rods are becoming as a revolutionary element in design and engineering applications. https://davenport-morse-2.technetbloggers.de/the-fate-of-electronic-devices-examining-conductive-grade-polyimide-based-substances for their exceptional thermal stability, chemical resistance, and mechanical strength, these high-quality polyimide rods are paving the way for innovations across multiple industries. As technology keeps to evolve, the ability to incorporate conductivity into lightweight materials unlocks new avenues for engineers and designers alike, particularly in demanding fields such as aviation.

The aerospace industry, in particular, is poised to gain greatly from the unique properties of electrically-conductive polyimide rods. As aircraft and spacecraft grow increasingly complex, the need for materials that can withstand extreme conditions while providing consistent electrical performance is essential. By employing conductive polyimide rods, manufacturers can enhance not just the functionality of their designs while also contribute to weight reduction, improving overall efficiency and performance in aerospace applications.

Advantages of Conductive Polyimide Rods

Conductive polyimide rods provide numerous key advantages to various industries, especially due to their superior thermal stability and high performance. Such rods can endure severe temperatures while maintaining their structural integrity, rendering them suitable for applications in challenging environments. This characteristic is crucial in fields such as aerospace, where materials are exposed to significant heat and stress. The ability to perform under such conditions ensures dependability and safety in essential components.

Another significant advantage of conductive polyimide rods is their superb electrical conductivity. Unlike traditional insulative polyimides, the incorporation of conductive fillers enables these rods to conduct electrical signals effectively. This feature opens new avenues for integrating electronic components into designs without compromising the benefits of polyimide, such as lightweight profiles and chemical resistance. The aerospace industry, in particular, can exploit this advantage for advanced wiring solutions and sensor applications, boosting overall performance.

Moreover, conductive polyimide rods exhibit remarkable chemical resistance, which is important for applications in environments where exposure to harmful substances is frequent. This durability contributes to lowered maintenance costs and extended service life of components. As a consequence, industries that need materials capable of enduring harsh chemical environments can benefit significantly from incorporating these rods into their designs, leading to improved efficiency and cost-effectiveness.

Applications in Aerospace Engineering

This aviation industry requires materials that satisfy strict operational specifications while ensuring lightweight and durability. Conductive polyimide rods are more and more becoming a favored choice because of their superior heat resistance and remarkable mechanical properties. Such rods can resist high heat and radiative forces, which makes them suitable for multiple applications in aircraft and spaceship design. This distinct blend of features allows engineers to develop components that are strong yet light, contributing to total fuel economy and capability.

Moreover, the electrical conductivity of conductive polyimide rods provides new avenues for integrating sensors and electronic systems directly into structural components. This capability is vital for contemporary aerospace systems that rely heavily on monitoring and control systems. By embedding these conductive rods inside aircraft body designs, engineers can minimize weight and avoid the issues associated with conventional wiring, enhancing both design efficiency and system reliability in aerial functions.

Lastly, the flexibility of these rods rods allows for their use in prototype development and manufacturing. With the ability to be molded into complex shapes, these rods enable creative design solutions that satisfy the evolving needs of the aerospace sector. Their application varies from structural reinforcements to specialized tooling, allowing for rapid production cycles and reducing market introduction time for new aerospace technologies. As the industry continues to progress, the role of these rods rods will be pivotal in ushering in next-generation aerospace solutions.

Manufacturing Processes

The manufacturing of electrically conductive polyimide rods entails a series of advanced techniques designed to achieve high performance and precision. Initially, the process begins with the preparation of polyimide resin, which is usually synthesized through the polycondensation of an aromatic compound diamine and a aromatic dianhydride. This step is critical as it determines the thermal and electrical properties of the end product. The addition of conductive fillers, such as black carbon or metallic particles, improves electrical conductivity while maintaining the desirable characteristics of polyimide.

After the resin is created, the next step centers on shaping the rods. This is usually achieved through methods such as extrusion or injection molding. In extrusion, the molten resin is pushed through a die to create long continuous rods, which are then chilled and cut to desired lengths. Injection molding, on the other hand, allows for intricate geometries to be created by injecting the heated resin into a mold. Both processes require precise temperature control and material handling to ensure quality and performance in the final product.

Following shaping, the rods go through a curing process to achieve the necessary mechanical and thermal stability. This involves heating the shaped polyimide in a controlled environment to facilitate cross-linking of the polymer chains. The curing temperature and duration vary based on the specific formulation of the resin and the target properties of the finished rods. Post-curing treatments may also be implemented to further enhance the rods' durability and conductivity, tailoring them for specialized applications in fields such as aerospace.

Emerging Trends and Advancements

As the requirement for light and high-performance materials continues to rise, conductive polyimide rods are positioned at the forefront of innovation. The aviation industry, in specific, is expected to adopt these materials in greater depth in the coming years. With the emphasis on decreasing weight while maintaining strength and performance, conductive polyimide rods provide an ideal solution for various applications, including building components and electronic systems within aviation vehicles. Advancements in coating techniques and fabrication methods are likely to boost the electrical conductivity and mechanical properties of these rods, which makes them even better suited for rigorous aerospace standards.

A further area of potential growth is the adoption of advanced manufacturing methods that leverage conductive rods made of polyimide in the manufacturing of advanced electronic devices. As the Internet of Things and advanced technology keep evolving, the necessity for materials that can smoothly connect with sensing devices and additional electronic parts will drive progress in polyimide mixtures. Innovative changes may include enhanced thermal and electrical conductivity, which could lead to possibilities for smaller form factors in electronics, automotive applications, and wearables.

Investigation and progress in biocompatible conductive rods made of polyimide are also on the horizon, which could change the medical and healthcare sectors. These materials could be used for implantable devices or intelligent medical tools that assess bodily functions while being safe for prolonged contact with bodily tissues. The persistent investigation of the chemistry of polyimides and working methods will undoubtedly open doors for discoveries that reveal novel applications across a diverse fields, reinforcing the importance of conductive polyimide rods in innovative designs.